Airbus formally activates A350 final assembly line

Airbus has begun assembly of the A350 static test airframe, MSN5000, at its Toulouse facility, officially activating the new final assembly line. The December arrival of the forward fuselage from St. Nazaire was followed Wednesday by the center fuselage built up at the same French site. With both now in Toulouse, Airbus formally began joining the major structural pieces at Station 59 inside the assembly line. The wings and aft fuselage from Broughton and Hamburg, respectively, will be arriving in Toulouse in the weeks to come, says Airbus. More photos below the fold.

Assembly of MSN1, the first flying A350 test aircraft, is slated to follow in July say program sources. MSN5000 won't require systems outfitting as MSN1 does, and will proceed through the normal assembly process.

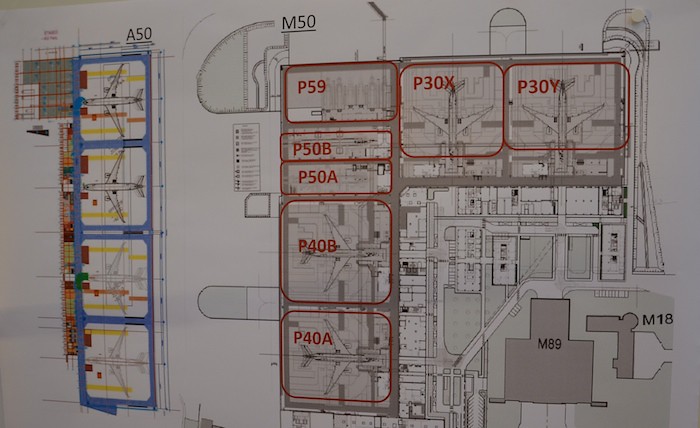

Here's a step-by-step overview of the A350 assembly flow:

Station 59

After arriving with sections from across the A350's pre-final assembly facilities, the fuselage structure is unloaded from the A300-600ST "Beluga" and are placed in a bay in the northwest corner of the final assembly line called Station 59. This pre-assembly position has room for two complete A350 airframes. Taking advantage of the open-ended fuselage sections, crews will install the primary interior monuments, flight and cabin crew rests without having to worry about access after the fuselage join begins.

Station 50

After the three main fuselage sections have been prepared at Station 59, each is moved toStation 50 to begin the full mechanical fuselage join. Here the nose landing gear will be installed along with a dummy main landing gear assembly to move the airframe to the next station. This full fuselage assembly is different from the A330, which begins assembly through the join up of the wings to a center fuselage barrel.

Station 40

Upon rollout from Station 50, the joined fuselage will move to the south to one of two main final assembly bays to Station 40. The wings are moved by crane into position and it is here where the join takes place, along with horizontal and vertical tail plane installations and power is first activated on the aircraft.

The A350 tooling is designed to allow the physical join to take place on separate levels from the cabin installations inside the fuselage, which can happen much earlier in the assembly process because the fuselage is ready for the interior fitting after the work at Station 50. Main landing gear installation takes place in Station 40 as well.

Station 30

The completed airframe is then towed from Station 40 to the north part of the final assembly line to one of two positions at Station 30 for cabin completion and aircraft system tests that include check-outs of the the flight controls, flaps, slats and landing gear.

Station 18

The aircraft is then moved outside for a first spate of ground tests that can't safely or practically be completed indoors, conducting pressurization and radio evaluations before moving to the paint hangar and then to the flight line.

Station 20

After being painted, the aircraft will be moved to Station 20, which is shared with the A330 line to the west of the main A350 final assembly building. It is here where the aircraft undergoes final cabin installations and fitting of its twin Rolls-Royce Trent XWB engines before moving to the flight line.

Photos Credit Airbus

Comments